hardness test on ni3nb through nanoindentation|nanoindentation hardness : import In last decades, some works pushed the nanoindentation of thin films forward by improving the nanoindentation results analysis for pure film hardness 33,34,35 and elastic modulus 32,34,35,36,37,38 . web23 de mar. de 2022 · janmy__uwu Nude. 14.02.2024. ⏩ Watch Mile Paladino Nude OnlyFans Leaks at Fappedia.

{plog:ftitle_list}

Resultado da 23 de abr. de 2023 · Musa do OnlyFans revela que ganhou convite de David Luiz: 'Saímos uma vez'. A musa do OnlyFans Júlia Calsing, 20, que .

Nanoindentation is an effective and powerful tool to detect local elastic properties and hardness of micro- and nanostructures of materials. The basic idea of nanoindentation is . Whereas it was first referred to as ultra-microhardness testing or nanoindentation testing because of the force and length scales involved, today, instrumented indentation .

The most common uses for hardness tests is to verify the heat treatment, carburization, etc., of a part and to quickly determine if a material has the properties necessary for its intended use. .

In last decades, some works pushed the nanoindentation of thin films forward by improving the nanoindentation results analysis for pure film hardness 33,34,35 and elastic modulus 32,34,35,36,37,38 .hardness and elastic modulus can be obtained, but also information such as vis- coelasticity, creeping, fracture toughness, strain-hardening effect, residual stress, phase transition, and .

Meyer, Knoop, and the nanoindentation hardness are defined as the ratio of the applied load L to the projected areas (A p or A pml) of the indent. Finally, the Rockwell, Shore, . A new testing system and techniques for measuring the hardness of materials subjected to very high indentation strain rates up to 104 s−1 is presented. This was .

nanoindentation hardness

Indentation test (Hardness test) • Hardness – resistance to penetration of a hard indenter

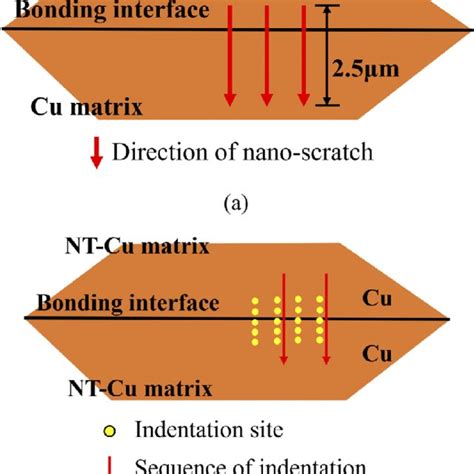

In this work, an analytical framework that includes the mechanical and electronic contributions of the instrument and the material constitutive response is presented to provide . 3.1 Nanoindentation characterization of the SS‑304L/Zy‑4 junction. The mean values of nanohardness (H) and Young’s modulus (E) for the base materials (SS-304L and Zy-4), including the various phases formed at the interface, are presented in Table 2.The base materials, SS-304L (γ-(Fe, Cr, Ni)) and Zy-4, exhibit nanohardness (H) values of approximately 3.06 .

Nanoindentation is a widely used state of the art facility to precisely and conveniently evaluate the mechanical properties of a wide group of materials. Along with the determination of elastic modulus and hardness of .

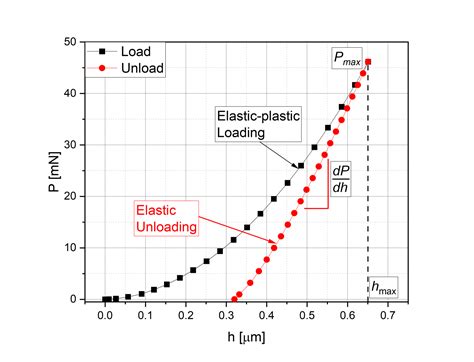

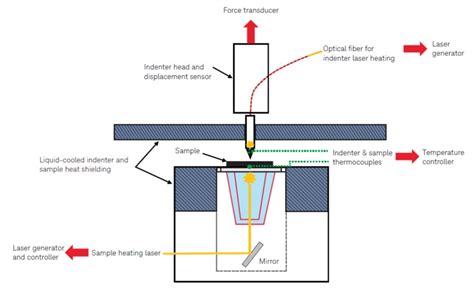

To measure nanomechanical properties of surface layers of bulk materials and thin films, depth-sensing nanoindentation measurement techniques are used commonly. The nanoindentation apparatus continuously monitors the load and the position of the indenter relative to the surface of the specimen (depth of an indent or displacement) during the .

nano indentation testing

Instrumented indentation test, also known as nanoindentation test, has been widely used to evaluate the local indentation hardness of materials at the nano- and micro-scales for academic and industrial purposes; it has been frequently compared with the Vickers hardness (HV) test used on larger scales [].A considerable number of studies have investigated the .

The analysis of load increments shows that tip defects affect the test result through statistically stored dislocation (SSD) and geometrically necessary dislocation (GND). Indenter tip defects mainly affect the nanoindentation test results through GND. The smaller the indenter tip radius, the higher the GNDs, and the higher the test hardness.Hardness • Hardness is a measure of a material’s resistance to surface penetration by an indenter with a force applied to it. • Hardness – Brinell, 10 mm indenter, 3000 kg Load F /surface area of indentation A – Vickers, diamond pyramid indentation • Microhardness – Vickers microindentation : size of pyramid comparable to microstructural features.

The determination of the mechanical properties of thin hard coatings has gained more importance recently in both research and industry. Up to now nanoindentation measurements were applied to determine the elastic and plastic properties of thin films [1], [2], [3] and corresponding high accuracy instruments have been developed [4].The pointed out .through a 10mm diameter hard ball onto the test material. The hardness of the material is calculated by measuring the diameter of the residual imprint. As materials increased in hardness over the years new techniques had to be developed to measure this property. Patented in 1914 the Rockwell Test employs smaller indenters; a diamond cone or a

Laser shock peening is a new and important surface treatment technique that can enhance the mechanical properties of metal materials. Normally, the nanosecond laser with pulse-width between 5 ns and 20 ns is used to induce a high-pressure shock wave that can generate plastic deformation in the top layer of metals. The femtosecond laser shock peening in the air . This research presents a comprehensive analysis of deep neural network models (DNNs) for the precise prediction of Vickers hardness (HV) in nitrided and carburized M50NiL steel samples, with hardness values spanning from 400 to 1000 HV. By conducting rigorous experimentation and obtaining corresponding nanoindentation data, we evaluated the .

In MD simulations, nanoindentation tests are usually modeled by forcing an indenter to penetrate a specimen. The indenter is commonly considered a rigid body during the simulation and may be designed to exhibit different geometries such as a cone or a half-sphere as shown in Fig. 5.11.In a manner similar to the procedure in an experimental nanoindentation test, an MD simulation . We use nanoindentation to measure the local elastic modulus and hardness of individual oxide particles, produced by precipitation within liquid iron, that belong to the systems Al 2 O 3 –SiO 2 –CaO and MnO–SiO 2 –FeO. Measured inclusion hardness values are typically in the range of 8 to 13 GPa and can reach 26 GPa for alumina-rich .Nanoindentation is vital for revealing the quantitative mechanical properties of small volumes of materials. Currently, this method is a standardized method for determining plastic, elastic, and visco-elastic properties of materials such as ceramics, biological materials hard thin films, soft films, multi-phase metals, semiconductors, and plastics on a micron to nanometer scale. It was evaluated using the nanoindentation hardness test results and a computational model developed in previous studies by the first author and his co-workers. Discover the world's research 25 .

nano indentation requirements

The three-sided Berkovich indenter is the most popular geometry for nanoindentation testing. A typical Berkovich indenter tip is shown in Fig. 1.The face half-angle of a Berkovich indenter used for nanoindentation work is 65.27°. ≈ 65.3°. This gives the same projected area to depth ratio as the more commonly used four-sided Vickers indenter (face . Nanoindentation, or instrumented indentation, has proven to be an extremely useful technique to characterize the mechanical properties of metals (Ref 1) and ceramics (Ref 2) at the microscale.Nanoindentation provides information on the measurement of hardness and elastic modulus (Ref 3, 4).This technique has been successfully used to measure, in .

ABSTRACT Ultra-small testing technologies (USTTs), such as nanoindentation hardness tests and micropillar compression tests, can be potentially used to measure the mechanical properties of irradiated materials. However, the hardness and yield strengths of USTTs are different from those of standardized methods on bulk samples. In addition, irradiation-induced defects can . Using samples fabricated by reactive sputtering, nanoindentation hardness depth profiles were correlated with practical scratch resistance using three different scratch and abrasion test methods .Comparison between nanoindentation and scratch test hardness (scratch hardness) values of copper thin films on oxidised silicon substratesMicrohardness testing and nanoindentation are standard methods of determining hardness. Nanoindentation has the added benefit of also providing elastic modulus. The hardness of a material is the single most important parameter when designing contacts. The harder material wears down the softer when in contact with each other.

Brinell hardness test (HB) BHN and HBW are widely used [7] Knoop hardness test (HK), for measurement over small areas, widely used to test glass or ceramic material. [8] Janka hardness test, for wood; Meyer hardness test; Rockwell hardness test (HR), principally used in the USA. HRA, HRB and HRC scales are most widely used. As an indicator of the material's ability against deformation, hardness has been studied for more than 100 years [1].Usually, a prescribed load is applied to an indenter in contact with a specimen and the area of the residual impression A r is measured often by optical imaging after the load is removed, the microhardness is then obtained through dividing the load by A r . Nanoindentation is a widely used technique to determine the mechanical properties of bone at the tissue level (Guo and Goldstein, 2000, Haque, 2003, Lewis and Nyman, 2008, Oyen, 2011, Rho et al., 1997, Zysset et al., 1999).In nanoindentation, a probe is brought into contact with a surface, pushed into the material, and retracted, while the load (P), . Interestingly, when comparing the results from the nanoindentation tests, it becomes evident that although Layer 1 has higher hardness, its adhesion is not better. From this, it’s apparent that the presentation of a thin film’s mechanical properties and adhesion isn’t always positively correlated.

instron tensile compression tester model 4481

Indentation test is a simple and effective method in the assessment of mechanical properties of materials and has widely been adopted in the latest century. Indentation technique evaluates the mechanical properties of materials by driving an indenter into the material surface and subsequently imaging the impression. Indentation test was firstly used for the measurement of .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

Thus, the Young's Modulus, E, can be obtained from: (1-2) 1 E r = 1 − ν 2 E + 1 − ν i 2 E i Where ν i = aggregate Poisson ratio of the diamond indenter is 0.07 [7] and E i . = Young's modulus of the diamond indenter.. The scratch test is a simple and widely used method for investigating adhesion in thin films [13], [14], [15].In the scratch test a Rockwell C diamond .

instron tensile compression tester model 4481 diagrams

2 girls 1 cup. Published 2 years ago • 68K views. 8 1 SHARE DOWNLOAD. l. Liveleak_Shitlord By gorelord_999. Subscribe. Using an ActivityPub account Subscribe .

hardness test on ni3nb through nanoindentation|nanoindentation hardness